Simple Power Op Amp Solutions

About PAD

- PAD was founded in 2002 to develop a new generation of power op amps for industrial applications

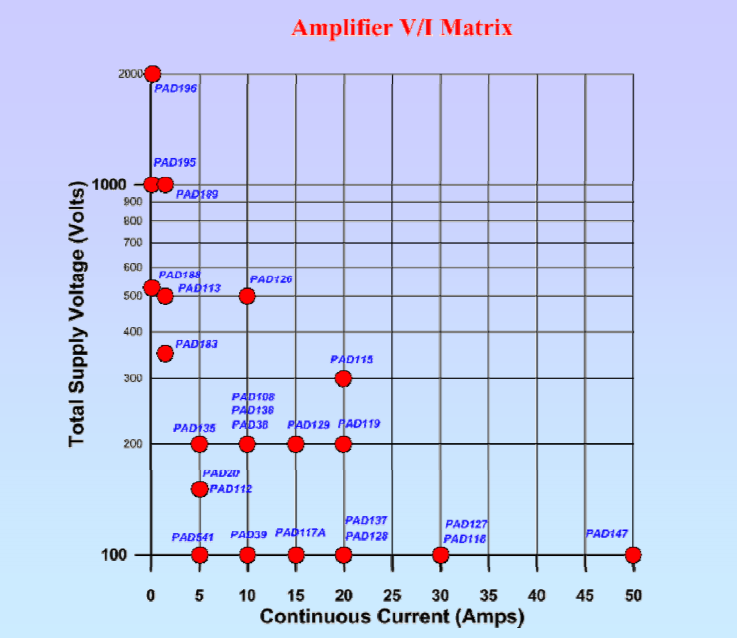

- PAD amplifier products span a voltage range of 100 to amplifier products span a voltage range of 100 to 2000V, current ratings , current ratings from 50mA to 50A and a power dissipation range from and a power dissipation range from 5W to 300W with footprints ranging from footprints ranging from 30mm square to square to 90mm square.

- Typical applications for PAD products include:

- Brush motor drive

- Sonar transducer drive

- Industrial Ink Jet Print Head Drive Industrial Industrial Ink Jet Print Head Drive

- Scanning tunneling microscopes

- ATE pin drivers

- Ultra-sound transducer drive sound transducer drive

- Scientific instrumentation

- Semi-conductor capital equipment conductor capital equipment

PAD Design Goals

- The new The new PAD products have achieved their products products have achieved achieved their power op amp design goals:

- Replace aging industry hybrid amplifiers with more Replace Replace aging industry industry hybrid amplifiers amplifiers with more modern and cost effective designs

- Improve power amplifier performance at a lower Improve Improve power amplifier amplifier performance performance at a lower cost than hybrid designs

- Provide an integrated cooling solution Provide Provide an integrated integrated cooling cooling solution solution Provide a compact simple plug & play power amplifier solution

PAD Design Support

- All PAD products are supported with:

- Expert applications assistance

- SPICE models for common circuit simulators SPICE models for common circuit circuit simulators simulators

- Evaluation kits for each model

- PAD Power™, our Excel based design verification spreadsheet

- Accessory modules to modify or enhance normal amplifier operation

- Custom designs with or without heat sinks & fans

PAD New Concepts

- PAD high power op amps offer a new concept: an integrated heat sink and fan optimize amplifier cooling while decreasing size and increasing power density

- PAD amplifiers are constructed with low cost surface mount technology on an insulated metal substrate and uses no beryllium oxide (BeO).

- PAD optional accessory modules to enhance am modules to enhance amplifier performance

PAD Amplifier Advantages

- Compact plug-in designs with integrated active and passive heat sink cooling

- Amplifier temp range from -40C to +105C (designs without fan and -55C to +125C temp range available on special )

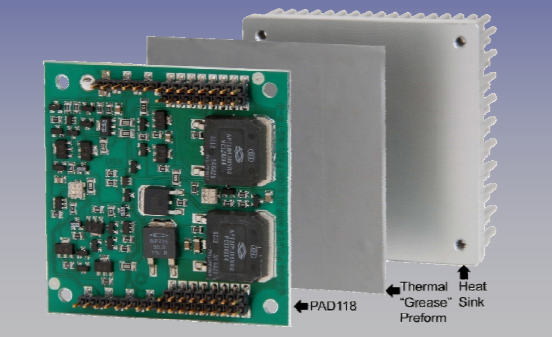

- No separate components to procure or assemble (heat sink, thermal “grease”, amplifier)

- Real-world power ratings (not relative to the “infinite” heat sinks of competitive products)

- Best technical specifications available.

- Many amplifier models offer thermal shutdown and analog temperature output voltage

- Extensive “accessory” modules offered

Active Cooling Comparisons

- Both heat sinks shown have a thermal resistance of 0.5oC/Watt

- Aavid passive heat sink volume is 100 in3 and weights 73 oz.

- PAD active heat sink volume is only4.6in3 and weighs only 4 oz.

- PAD cooling fan consumes only 1.5 watts

Amplifier Attachment

- Amplifier pre Amplifier pre-attached to heat sink with heat and pressure for a high quality interface

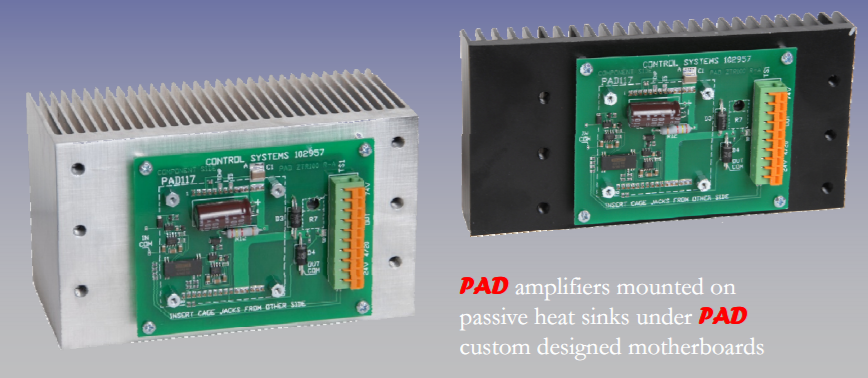

PAD Products Also Available on Custom Passive Heat Sinks for Special Applications

PAD Accessory Modules Accessory Modules

- Optional accessory modules offer new features to amplifier models

- For example: model PAD125 offers programmable current limit features

- PAD131 offers PRIO operation for some models

PAD Evaluation Kits

- Most amplifier models offer dedicated evaluation kits for circuit development

- Evaluation kits are assembled and include all special components needed for the model

- Evaluation kits provide support e support for optional accessory modules

PAD Noted Customers

- General Electric

- NASA (Jet Propulsion Laboratory)

- General Motors

- Kodak

- Lockheed Martin

- NATO Undersea Research Centre

- Texas Instruments

- Schlumberger

- National Semiconductor

Conclusion

- PAD offers a full and expanding line of power operational amplifiers for industrial applications that offer superior electrical and thermal in a compact and plug-in design PAD products are supported by expert application assistance, accessory modules, SPICE models, evaluation kits and our PAD Power™ design spreadsheet.