Downloads

Evaluation Kit

EVAL183

Rev B

INTRODUCTION

The EVAL183 evaluation kit provides a convenient method to become familiar with the operation of the PAD183 Compact High Voltage Op Amp before your application circuit is committed to production. Some assembly is required since user selections are needed depending on the application. For example, there are several PCB mounting options available.

Critical connections for power supply bypassing and compensation are pre-wired. Connections are also provided for diode clamps on each power supply and the output for additional amplifier protection. Terminal strips are provided for input and output signals and power.

ASSEMBLY STEPS

Please note that the #1 cause of problems for evaluation kit users is not reading and following the directions (all of them). The #2 cause of problems is poor solder joints (cold or bridging). Don’t become a statistic. ✓ each step.

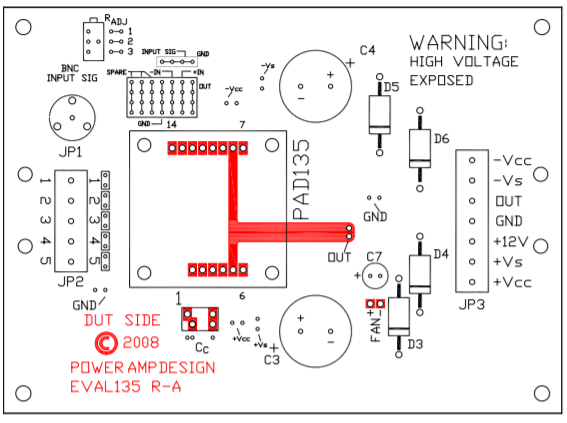

Refer to the Illustrated Parts List for the components mentioned in the assembly steps. Notice that the same circuit board is used for the EVAL135 and that the circuit board is marked as such. Also note that the DUT location is marked as PAD135. Although the EVAL183 uses the same circuit board as the EVAL135 there are component value differences.

1. Notice that the printed circuit board (PCB) is labeled on one side as the “DUT SIDE” and the other side as “CIRCUIT” side.

2. As shown in the illustrated parts list, one or more of PAD’s accessory cage jack strip CJS01 was used in the assembly of this kit. It may be advisable to use the cage jack strips in your production circuit board as well. The CJS01 cage jack sockets provide a convenient and inexpensive socket. Soldering and/or de-soldering the amplifier from the circuit board can be extremely difficult due to the high thermal conductivity of the amplifier’s pins and substrate. You can find the datasheet for the CJS01 on the PAD website under the “Accessory Modules” tab.

3. D3 and D5 are transient voltage suppressor diodes and are not supplied since the type (breakdown voltage) varies with the application. They are not necessary for every application. They are most commonly used in application circuits where kickback from the load may force the supply voltage above the limits of the amplifier.

4. The evaluation kit PCB can be mounted in several ways: Option 1- Chassis mount. Use #6 standoffs and screws (not supplied) attached to the PCB at the four corners of the PCB. Option 2- Bench-top mount. Use the five rubber bumpers supplied. These are “stick-on” components. Remove the release paper from each bumper and apply the bumper to the square outlines on the “CIRCUIT SIDE” of the PCB. Option 3- DIN rail mount. The PCB can be mounted to a 35mm DIN rail. For mounting the PCB to a DIN rail press the adaptors into the PCB in the holes at the edges of the PCB at locations 1 and 2 from the “CIRCUIT SIDE” of the PCB. Make sure that the plastic tines have fully spread out on the “DUT SIDE” of the PCB.

5. Remove the 4 hex nuts from the mounting spacers of the PAD183.

6. Align the 4 studs of the mounting spacers with the mounting holes in the PCB. Be sure that the amplifier’s pin 1 aligns with pin 1 on the PCB. Slowly lower the amplifier into the PCB, making sure that the pins of the amplifier and the cage jacks mate. Push the amplifier into the PCB until the mounting spacers meet the PCB.

7. Fasten the amplifier to the PCB with the 4 hex nuts previously removed. Do not over-tighten the nuts as this may strip the mounting studs. The provided plastic nut starter can assist you here.

8. If necessary, strip 1/8” of insulation from the wires connected to the fan. Twist and tin the wire ends. Insert the red wire into the cage jack labeled “+” at the location marked “FAN” on the PCB. Likewise insert the blue or black wire into the cage jack labeled “ ─” at the location marked “FAN”. Do not solder the wires into the sockets.

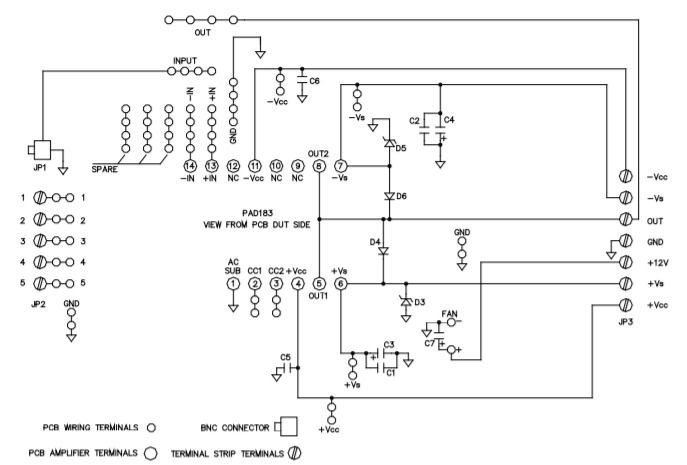

9. Use the bread-boarding area near pin 14 on the PCB to add the external components necessary to program the amplifier gain and other circuit requirements to evaluate your application circuit. You can use the evaluation kit schematic and PCB views to map out your circuit.

10. Remember that the PAD183 must be compensated to operate correctly. See the PAD183 datasheet on Page 4, under PHASE COMPENSATION. The selected phase compensation capacitor will be installed at “CC” on the evaluation kit PCB. A 47pF capacitor has already been installed in your kit. Another value may better suit your application. Remove and replace the capacitor as necessary for your application. 22pF and 150pF capacitors are also included with the kit. CC must be rated for at least 350V. A temperature stable type capacitor is required—an X7R ceramic, for example, or an NPO type (preferably).

11. The evaluation kit assembly is complete. Be sure you have read and followed all the assembly steps. Inspect the circuit board for solder shorts or poor solder joints. An illuminated magnifier is helpful.

12. Before applying power to your circuit set the power supply for ±20V and set the power supply current limit to approximately 100mA. Use little or no load at first. Apply an input signal and check the output with an oscilloscope to verify proper functionality. This step can prevent damaging the amplifier or the circuit board should there be some mistake in assembly.

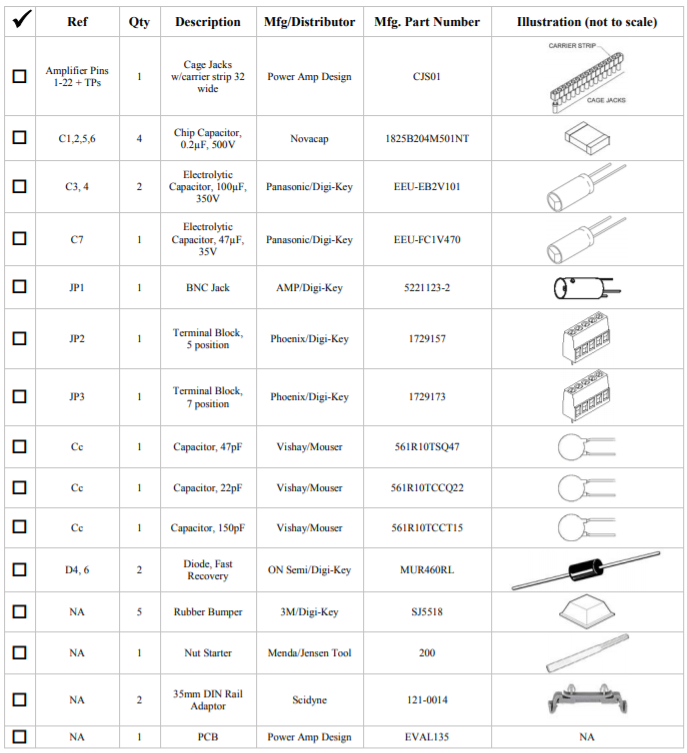

ILLUSTRATED PARTS LIST

Note that the PAD183 is purchased separately.

CIRCUIT & CONNECTIONS

CIRCUIT DIAGRAM

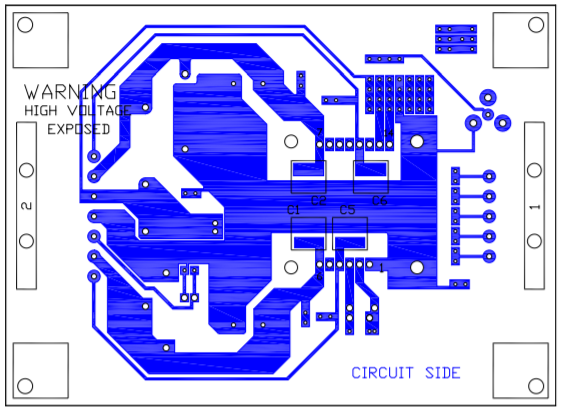

PCB VIEWS

TOP VIEW

BOTTOM VIEW

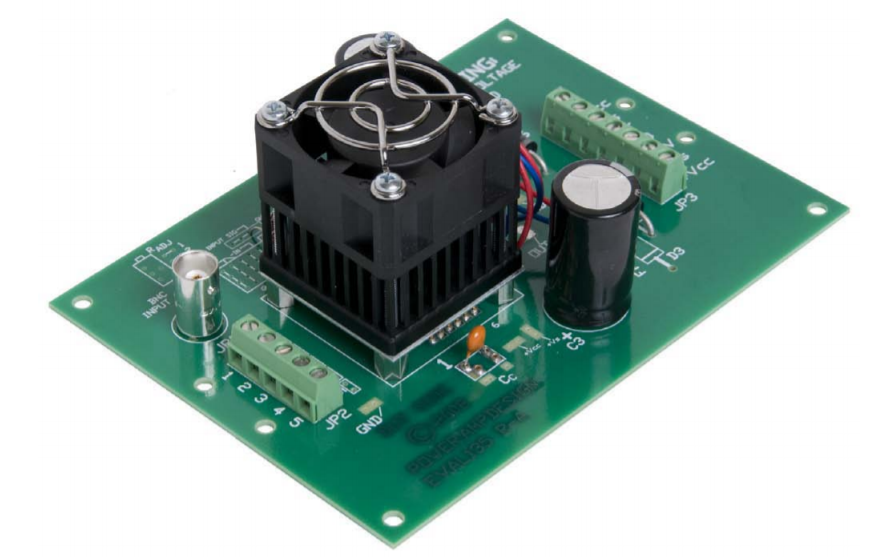

ASSEMBLED KIT

ASSEMBLED EVAL183

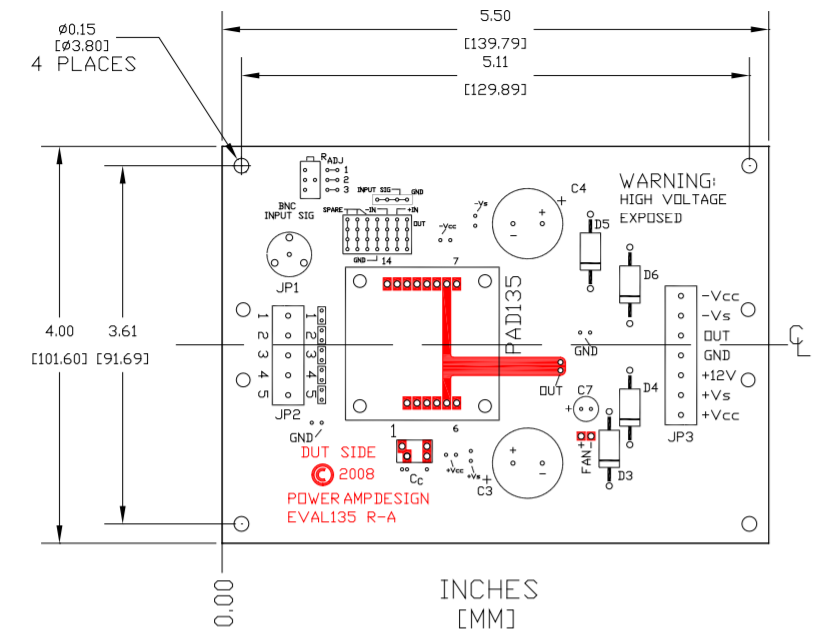

DIMENSIONAL INFORMATION

BOARD OUTLINE DIMENSIONS